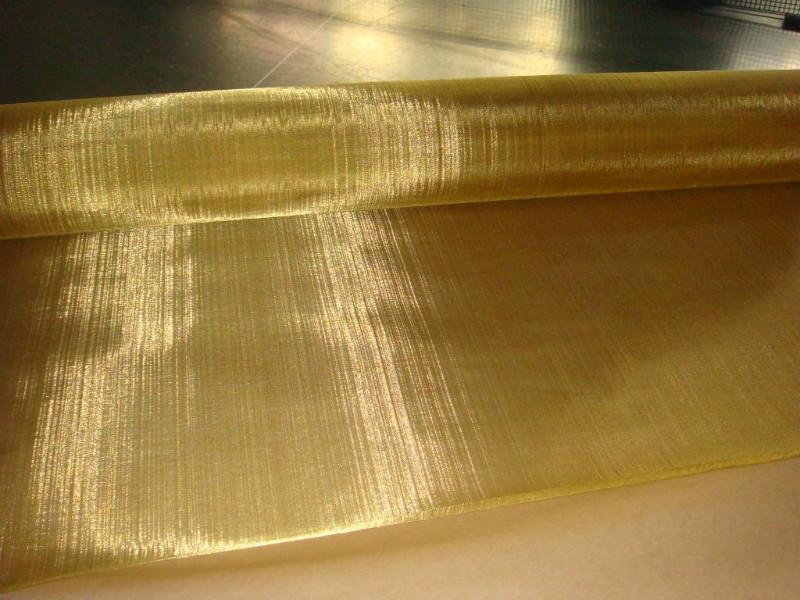

Material

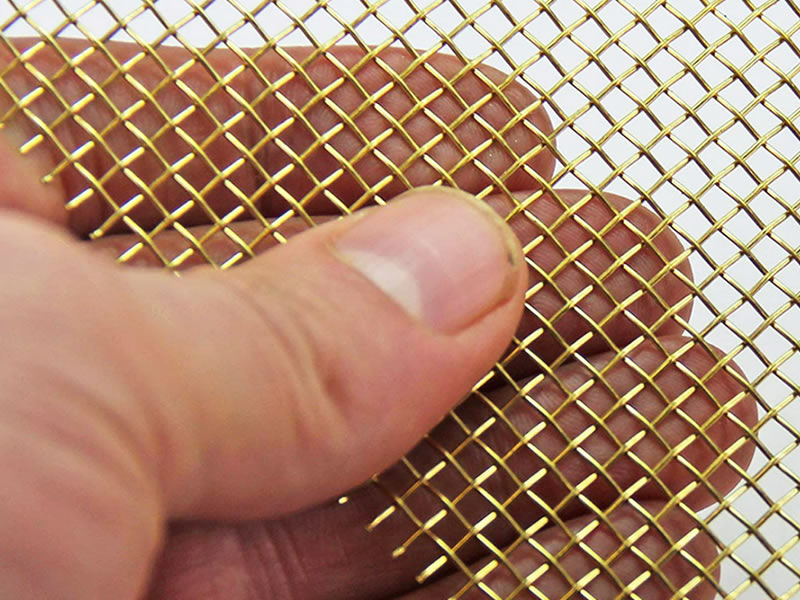

Brass woven mesh is fabricated using brass wire, an amalgam of copper and zinc, ensuring durability and versatility. The primary materials utilized in its construction are the H65 and H80 brass wire types.

H65 Brass Wire: Identified as Low Brass Type-H65, this variant comprises 65% copper and 35% zinc. It balances malleability with adequate strength, making it suitable for applications requiring both formability and resilience.

H80 Brass Wire: Known as High Brass Type-H80, this material contains a higher copper content at 80%, with 20% zinc. This composition enhances the mesh’s corrosion resistance and overall durability, making it preferable for environments prone to corrosive elements.

The choice between H65 and H80 brass wires allows for customization based on specific requirements, with H65 providing flexibility and H80 offering increased resistance to wear and environmental factors. Brass wire mesh’s superior abrasion and corrosion resistance, along with reduced electrical conductivity when compared to copper wire, make it an ideal choice for a wide range of applications, from filtration systems to architectural details.

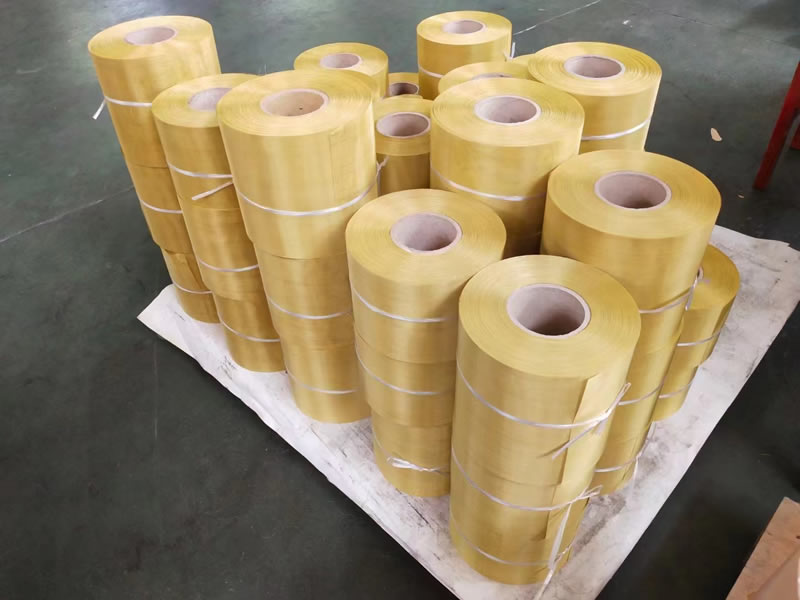

Applications

Our brass woven wire cloth products are extensively used across various industries, including mining, petroleum, chemical, electronics, transportation, plastics, food, and construction.

Aerospace and Marine: In these industries, brass woven mesh is used for its corrosion resistance and durability, essential for parts exposed to harsh environments.

Architectural Features: Ideal for high-end infill panels, room separators, and dividers, brass mesh adds elegance and functionality to architectural designs.

Art and Design: Artists and metal artisans favor brass mesh for its versatility in creating unique artistic designs, decorative lamp shades, and signage.

Filtration and Screening: Its utility in air and liquid filtration systems, oil strainers, and plumbing screens showcases its efficiency in separating and filtering diverse materials.

Home and Garden: Brass mesh serves aesthetic and practical purposes in fireplace screens, gutter guards, air vents, and soffit screens, blending durability with design.

Industrial Applications: Used in chemical processing, metal castings, and power generation, brass mesh’s properties meet the demanding conditions of these sectors.

Decorative Elements: Its application extends to cabinet screens and ceiling panels, where it combines functionality with decorative appeal.

| Mesh/Inch | Wire Diameter(mm) | Aperture(mm) | Open Area % |

| 4 | 1.2 | 5.15 | 65.8 |

| 5 | 1 | 4.08 | 64.5 |

| 6 | 0.71 | 3.52 | 69.2 |

| 8 | 0.5 | 2.67 | 70.7 |

| 10 | 0.5 | 2.04 | 64.5 |

| 12 | 0.45 | 1.66 | 61.5 |

| 14 | 0.4 | 1.41 | 60.4 |

| 16 | 0.3 | 1.28 | 65 |

| 18 | 0.25 | 1.16 | 67.6 |

| 20 | 0.25 | 1.02 | 64.5 |

| 30 | 0.21 | 0.64 | 57.1 |

| 40 | 0.19 | 0.45 | 50.2 |

| 50 | 0.15 | 0.36 | 50.1 |

| 60 | 0.15 | 0.27 | 40.7 |

| 80 | 0.12 | 0.197 | 39 |

| 100 | 0.1 | 0.154 | 37 |

| 120 | 0.09 | 0.122 | 33.2 |

| 140 | 0.07 | 0.111 | 37.6 |

| 150 | 0.06 | 0.109 | 41.5 |

| 160 | 0.06 | 0.098 | 38.1 |

| 180 | 0.053 | 0.088 | 41.6 |

| 200 | 0.05 | 0.077 | 36.7 |

| Note: Special size and specification can be customized. | |||