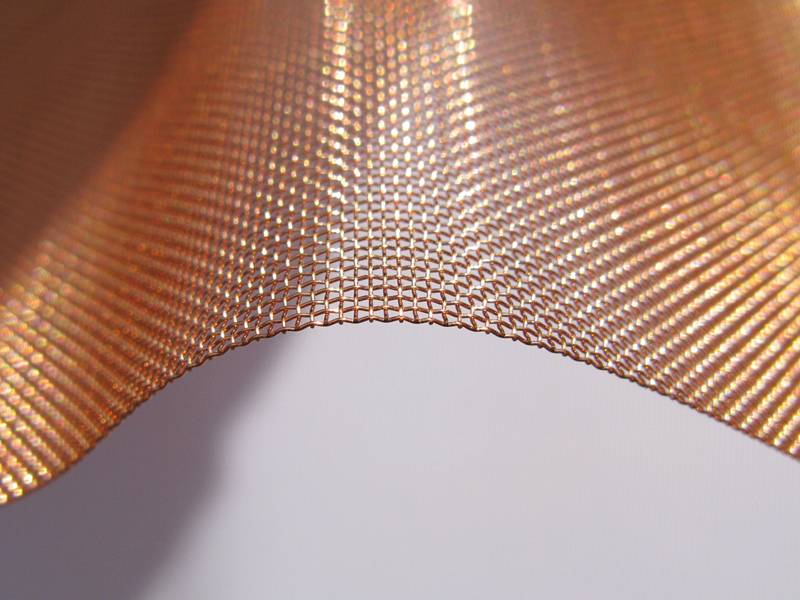

Designed to shield against radio frequency interference, RFI shielding wire mesh plays a vital role in protecting electronic devices. Made from copper for optimal conductivity, it effectively blocks intrusive electromagnetic signals. Essential in electronics, medical, and defense sectors, this mesh is crucial for preserving signal clarity and integrity.

Material

- Copper Wire Construction: RFI shielding wire mesh is primarily made from copper wire, known for its exceptional electrical conductivity. This material choice is crucial for its effectiveness in blocking radio frequency interference, making it indispensable in fields that require signal integrity, such as electronics, medical devices, and defense.

- Wire Diameter: The wire diameter for RFI shielding wire mesh varies from 1.6mm to 0.12mm. This range allows for the customization of the mesh to suit specific shielding requirements, balancing flexibility with protective capabilities.

- Mesh Count: Available in a mesh count from 2 to 200, this wire mesh can cater to a broad spectrum of RFI shielding needs. The variation in mesh count enables the mesh to be tailored for different levels of protection against electromagnetic interference.

- Roll Dimensions: Roll widths range from 0.6m to 2.9m, and roll lengths from 10m to 100m, providing considerable flexibility in coverage and application. These dimensions allow for the mesh to be used in various installations, from small-scale electronic enclosures to larger protective barriers.

- Weave Styles: Offering plain weave, twill weave, and intercrimp/lock weave styles, the RFI shielding wire mesh can be customized to meet specific performance criteria. Each weave style contributes to the mesh’s overall effectiveness and application suitability.

- Packaging Details: Ensuring the mesh’s protection during transport and storage, it is packaged with inner kraft paper and an outer layer of plastic cloth, then placed into a wooden pallet or case. This meticulous packaging ensures the mesh arrives in optimal condition for use.

Features

- Electromagnetic Shielding: Copper-based RFI shielding wire mesh excels in blocking and redirecting electromagnetic radiation and interference, making it indispensable for EMI shielding across a range of applications.

- Electrical Conductivity: Renowned for its superior electrical conductivity, this mesh plays a crucial role in ensuring effective electrical grounding and conductivity in various shielding scenarios.

- Corrosion Resistance: Its copper composition provides natural resistance to corrosion and oxidation, promoting durability and a longer lifespan, particularly in challenging environmental conditions.

- Ductility: The ductile nature of copper shielding mesh allows for ease in customization, enabling it to be effortlessly formed, molded, or shaped to meet specific design requirements and applications.

- Versatility: Designed for flexibility in application, RFI shielding wire mesh is available in multiple forms, including sheets, tapes, and gaskets, catering to diverse shielding needs.

Applications

- Electronic Enclosures: Copper shielding mesh lines electronic enclosures to protect against electromagnetic interference, preserving the performance of sensitive components.

- Cable Shielding: Used around cables and wiring, it shields from external electromagnetic interference, maintaining signal integrity and preventing leakage.

- EMC Testing: In EMC testing chambers, copper mesh creates controlled environments to assess electromagnetic compatibility.

- Aerospace and Defense: Essential in protecting avionic and military equipment, ensuring sensitive electronic systems are free from external interference.

- Medical Equipment: Applied in medical devices to block electromagnetic interference, crucial for their accurate operation and patient safety.

- Consumer Electronics: Integrated into smartphones, tablets, and computers to shield internal components from interference, enhancing device functionality.

- Automotive Electronics: Shields electronic systems and sensors in vehicles from interference, crucial for performance and safety.

- Telecommunications: Ensures signal quality and reliability in telecommunications equipment and infrastructure.

- Scientific and Laboratory Equipment: Critical in scientific instruments to ensure precision and accurate measurements, unaffected by external electromagnetic sources.