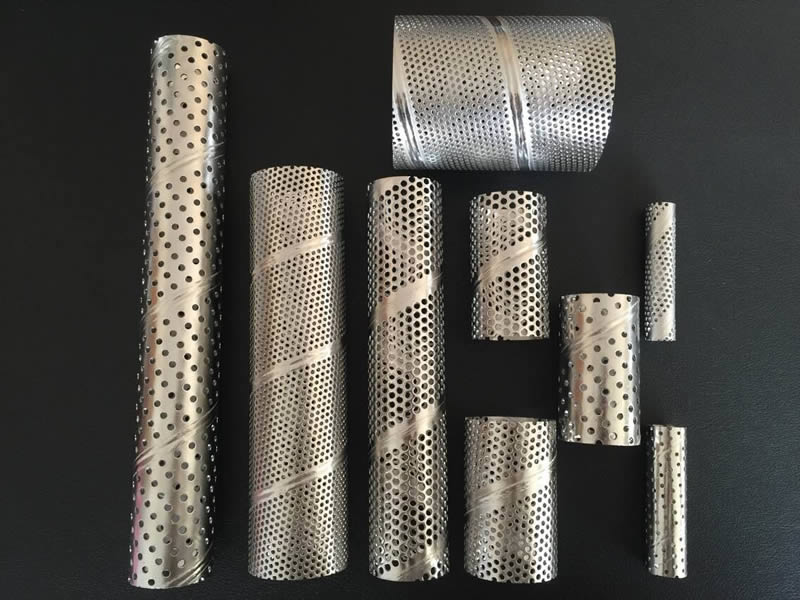

Perforated tubes, with their durable construction and flexible hole designs, are perfectly suited for high-pressure filtration and separation processes. Essential in sectors like automotive, petrochemical, and water treatment, these tubes deliver enduring durability and are designed to withstand wear and corrosion, ensuring reliable performance across various applications.

Specifications

Diameter Range

- Small Diameter Tubes: Available in diameters of 10mm, 15mm, and 20mm. These sizes are suited for precise applications such as medical devices, small-scale filtration systems, and detailed architectural elements.

- Medium Diameter Tubes: Comprising diameters of 25mm, 30mm, and 35mm. These mid-sized tubes are versatile, ideal for moderate filtration needs, automotive components, and decorative uses in construction.

- Large Diameter Tube: Offering a diameter of 500mm. This size is tailored for extensive applications including industrial filtration, large architectural projects, and infrastructure development, providing substantial coverage and capacity.

Length Options

- Short Lengths: Consist of lengths such as 50mm, 100mm, and 200mm. Perfect for compact projects or when smaller segments of tubing are required for specific functionalities.

- Standard Lengths: Including lengths of 500mm and 1200mm. These are commonly used in a variety of industrial, commercial, and architectural applications where standard size tubes can be efficiently utilized.

- Custom Lengths: Catering to unique project requirements, lengths can be customized beyond the standard options to meet specific design or application needs.

Margin Specifications

- Length Margins: A standard minimum margin of 20mm along the tube’s length ensures stability and facilitates handling during installation or integration into larger systems.

- Width Margins: The width margin can start from 0mm, maximizing the perforated area of the tube. Width margins are adjustable based on client specifications to align with project requirements, offering flexibility in design and application.

Features

- Formability: Perforated tubes are highly adaptable, allowing for easy shaping and forming to fit specific design requirements or installation needs.

- Polishability: These tubes can be polished to achieve a high-gloss finish, enhancing their appearance for decorative or aesthetic applications.

- Ease of Installation: Designed for straightforward installation, perforated tubes can be quickly and efficiently set up in various environments.

- Uniformity: They boast consistent openings and strength across the structure, ensuring even performance and aesthetic coherence.

- Thickness Diversity: A broad spectrum of thicknesses is available, accommodating different durability and application needs.

- Hole Variety: Offers an extensive selection of hole sizes, patterns, and configurations, providing versatility for custom projects.

- Abrasion Resistance: Perforated tubes exhibit superior resistance to wear and abrasion, extending their lifespan in harsh conditions.

- Dimensional Accuracy: Precision in size and dimensions is a hallmark of these tubes, ensuring they meet exact specifications for fit and function.

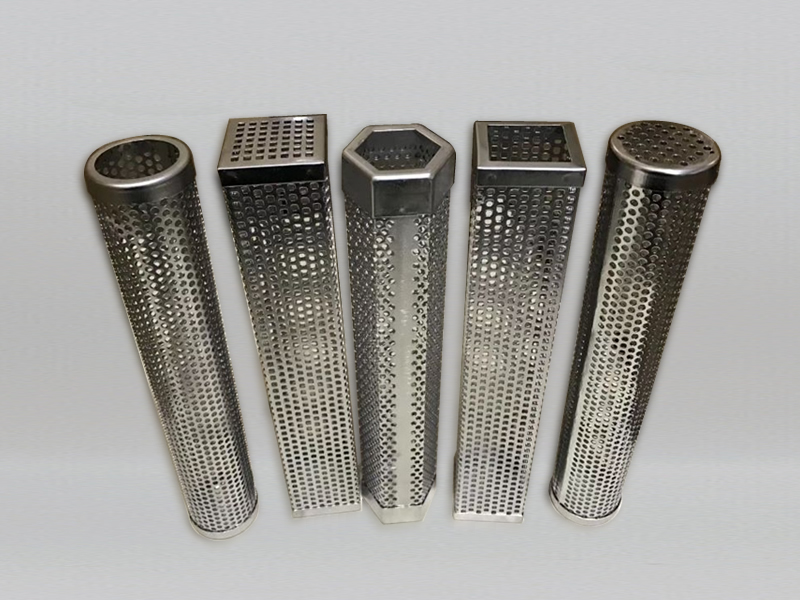

Hole Patterns

- Round Holes: The most common and versatile pattern, suitable for a wide range of applications, offering balanced open area and strength.

- Rectangular Holes: Ideal for specific filtration requirements, allowing for directional flow and unique aesthetic designs.

- Square Holes: Provide uniform strength and open area, used in applications requiring symmetrical designs and efficient filtration.

- Triangle Holes: Offer a unique aesthetic and are used in applications where design differentiation is key.

- Diamond Holes: Known for their aesthetic appeal and structural integrity, diamond holes are often used in architectural and decorative applications.

- Hexagonal Holes: Provide high open area and strength, commonly used in high-throughput filtration applications.

- Cross Holes: Feature a cross-shaped pattern, adding both functional and decorative value to the tubes.

- Slotted Holes: Ideal for separating and filtering elongated particles, offering directional flow characteristics.

- Custom Patterns: Perforated tubes can also be customized with unique patterns based on specific drawings or application requirements, ensuring versatility and personalized solutions for diverse projects.