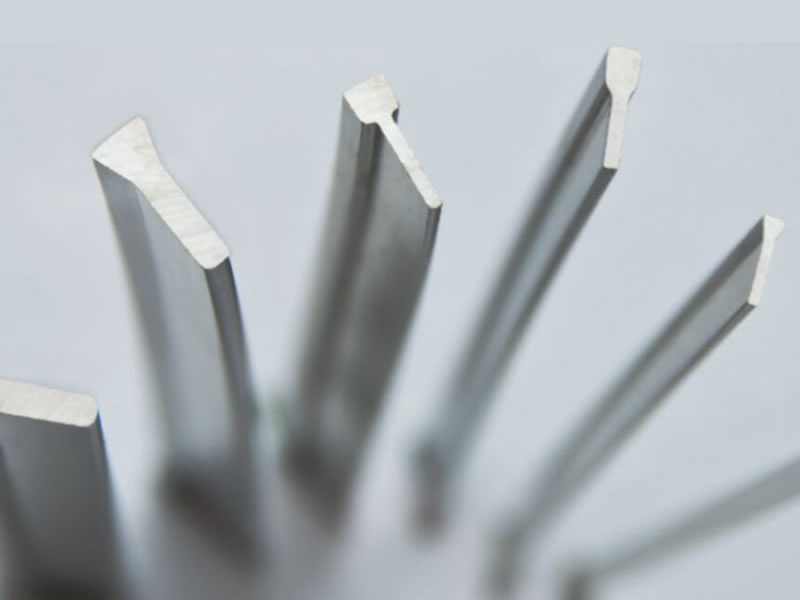

Wedge wires, noted for their distinct profile and expansive open area, are perfectly suited for filtration and screening tasks that demand effective fluid passage and reduced blockage. These wires are widely utilized in sectors like water treatment, food and beverage manufacturing, and chemical processing, contributing to increased efficiency and dependability within these industries.

Materials

Wedge wires are manufactured from a variety of materials to ensure optimal performance across diverse applications. The primary materials include:

- Stainless Steel: Grades such as 304, 316, and 316L are frequently utilized, accommodating applications in water treatment, food and beverage processing, and chemical industries.

- Carbon Steel: For applications where stainless steel’s corrosion resistance is not necessary, carbon steel offers an economical alternative. It’s typically used in less corrosive environments or where temporary solutions are needed.

- Alloy Materials: Special alloys, such as duplex stainless steel, Hastelloy, and Inconel, are used for wedge wires in more demanding applications.

- Wedge wires, with their diverse material options and customization capabilities, offer reliable solutions for filtering and screening across numerous industries.

Types of Wedge Wire

- Cylinder Type: Cylinder type wedge wires are designed for radial filtration, typically used in applications requiring cylindrical screens, such as water treatment processes and chemical filtration systems.

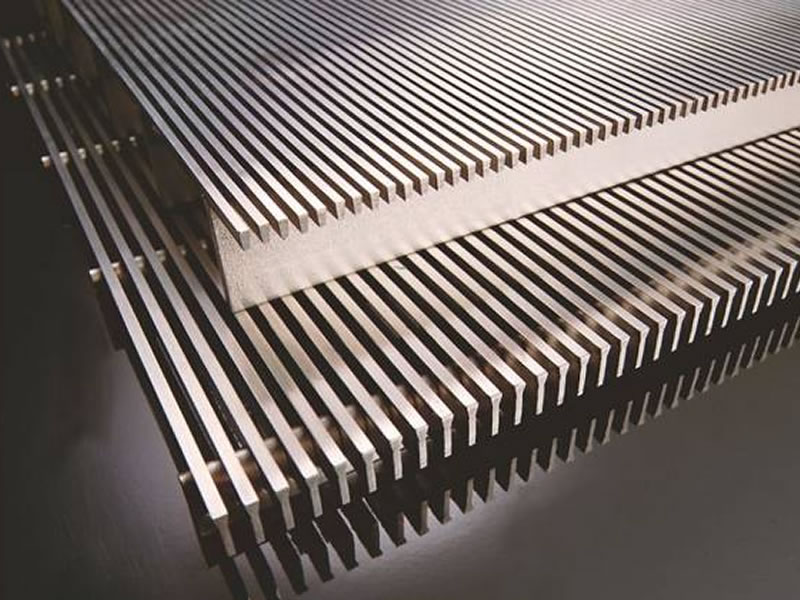

- Flat Type: Flat type wedge wires are utilized for linear screening and filtration. This variety is often applied in architectural designs, machinery guards, and various flat screening applications.

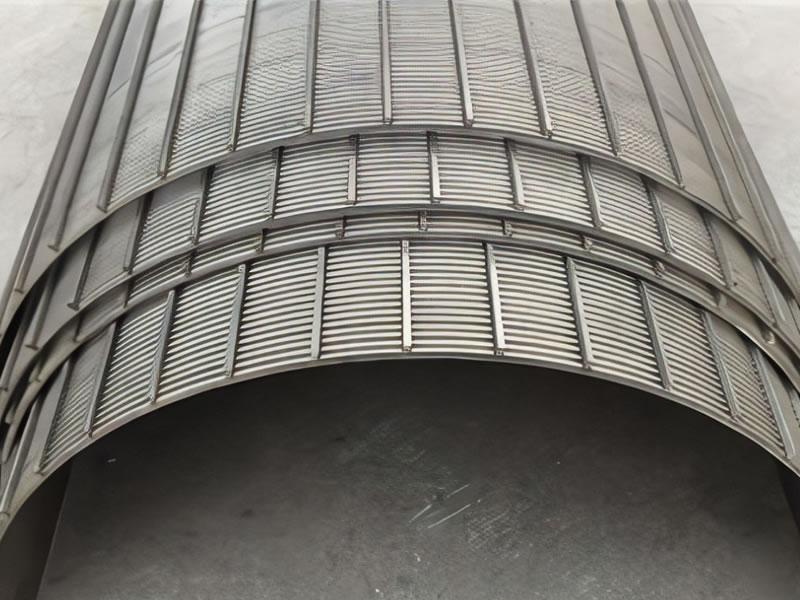

- Sieve Bend Type: Sieve bend type wedge wires are specially curved screens ideal for static sieving, offering efficient separation and filtration in mining, agriculture, and food processing.

- Basket Type: Basket type wedge wires are structured for centrifugal separation, commonly used in waste treatment, food processing, and chemical industries to separate solids from liquids.

Features

- Anti-Clogging Design: The unique wedge-shaped profile is designed to prevent clogging, ensuring an uninterrupted flow. If particles manage to penetrate the filter surface, the progressively larger openings facilitate their passage without blocking the system.

- Structural Rigidity: Wedge wire’s construction is exceptionally rigid, enabling it to endure vigorous cleaning routines and maintenance without succumbing to failure or deformation. This feature allows it to support higher operating pressure differentials reliably.

- Ease of Cleaning: Thanks to its smooth filter surface, cleaning wedge wire screens is both quick and efficient. Contaminants are easily released, making backwashing significantly more effective compared to other filter media. The wedge shape of the openings increases backwash velocity, enhancing the removal of particulates and ensuring thorough cleaning.