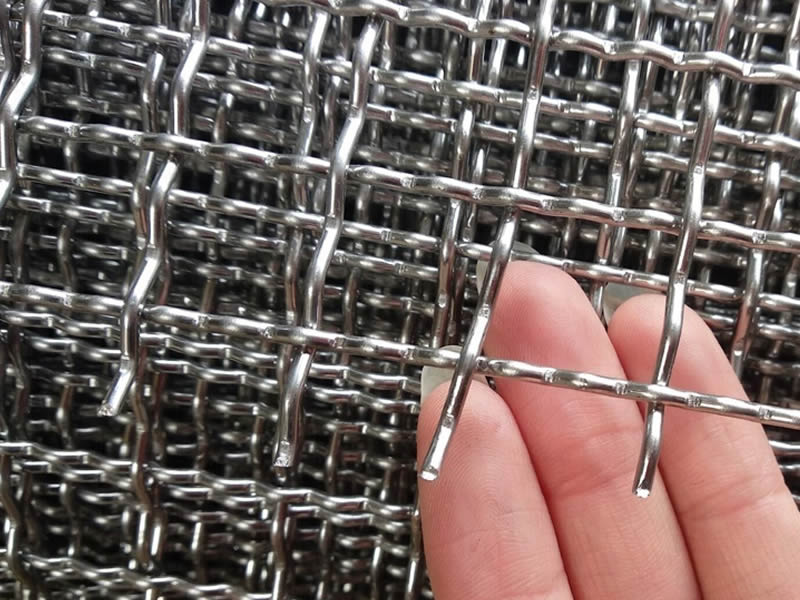

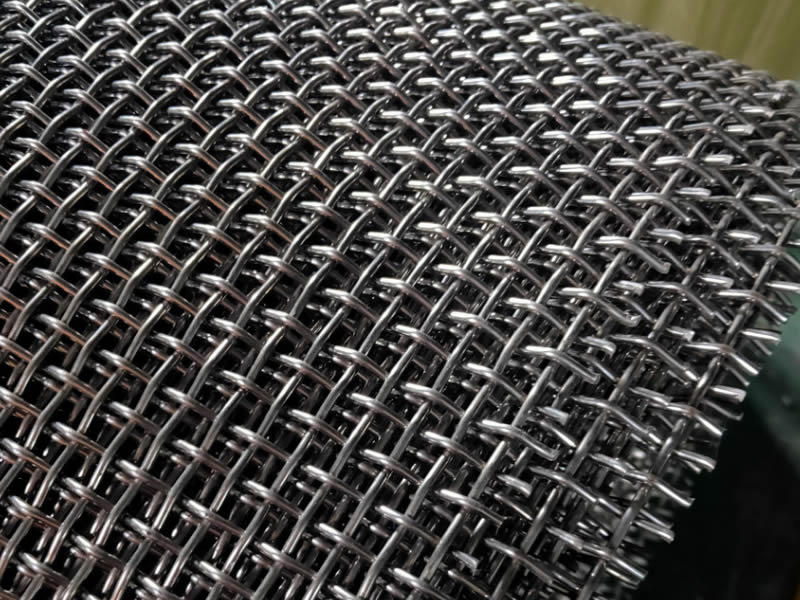

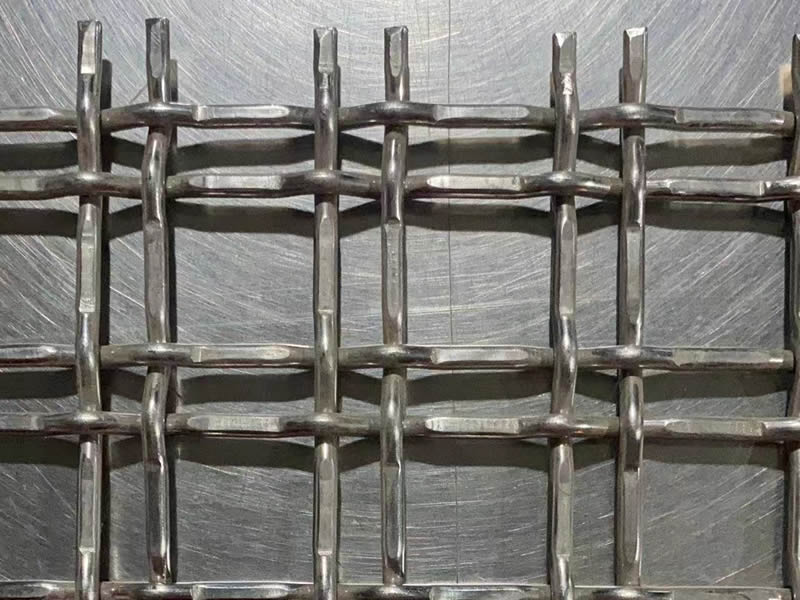

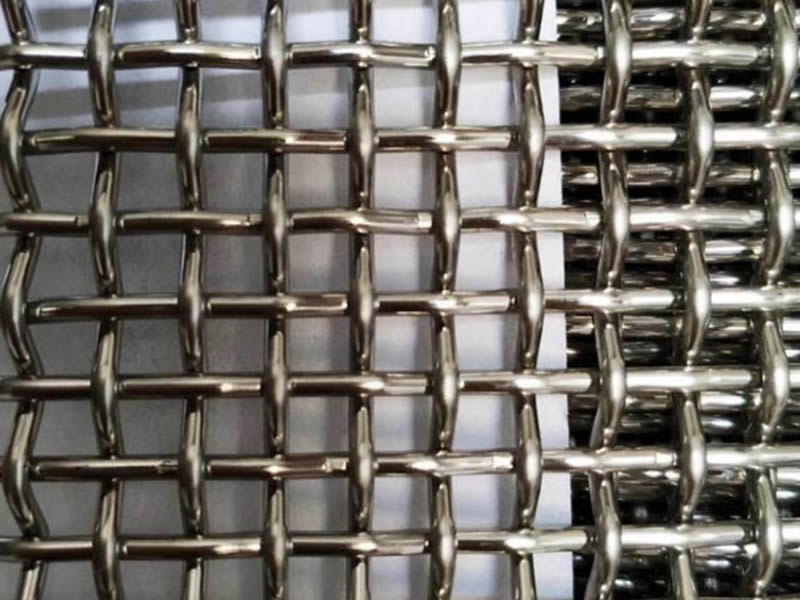

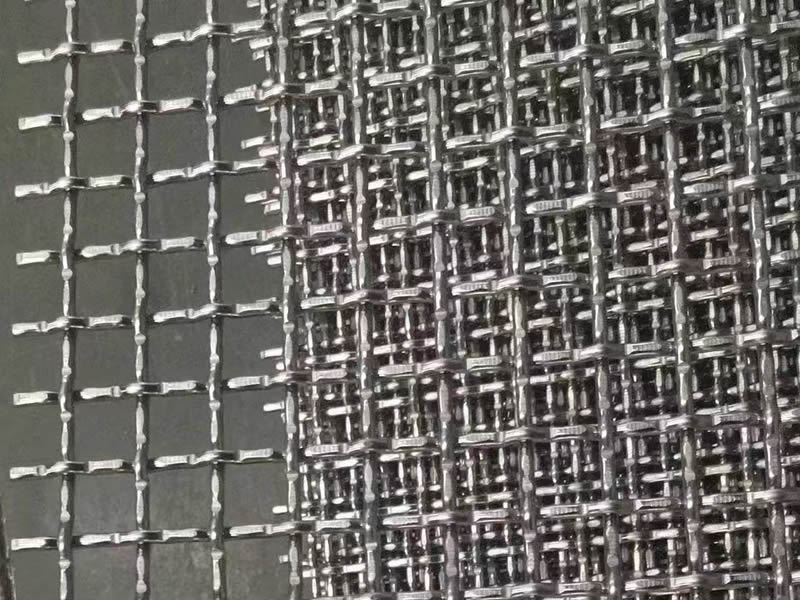

YuHeRen Wire Mesh Products Co., Ltd. specializes in producing and exporting Stainless Steel Crimped Wire Mesh. Our process involves pre-crimping wires before weaving, ensuring stable and uniform meshes. This method enhances the mesh’s structural integrity and offers various crimping styles for efficiency, functionality, and aesthetics. Ideal for diverse applications, our crimped wire mesh delivers reliable performance and visual appeal.

Specifications

Detailed below are its general specifications, including material options, wire diameters, aperture sizes, and dimensions.

Material Options

Stainless Steel Grades: We offer grades 304, 304L, 316, and 316L to accommodate various environmental conditions and application demands, ensuring durability and corrosion resistance.

Special Alloys: For specialized needs, our selection includes 310 stainless steel, Titanium mesh, Nickel Mesh, Monel wire mesh, and Chrome alloy iron. Each alloy offers unique properties, such as high-temperature resistance and exceptional strength.

Wire Diameter

Variety: Our wire diameters range from 0.5mm to 8mm. This variety allows clients to choose the appropriate mesh strength and flexibility for their specific application, from light filtration tasks to heavy-duty barriers.

Aperture Sizes

Range: Aperture sizes span from 1.0mm to 100mm. This broad range supports a spectrum of functions, including fine filtration, separation processes, and providing protective barriers in different settings.

Roll Widths

Standard Sizes: Typically available widths include 40″, 48″, and 60″, accommodating standard project requirements with ease.

Extended Options: For larger-scale applications, we provide widths up to 4 meters, ensuring coverage for extensive areas without compromising on quality.

Roll Lengths

Standard Lengths: Our rolls are usually available in lengths of 15m and 30m, suitable for a wide range of installations.

Extended Rolls: Lengths can reach up to 100 feet, offering solutions for extensive projects.

Customization: Understanding that projects can have unique requirements, we offer customized sizes.

Customized Sizes

This diverse range in material, size, and customization makes Stainless Steel Crimped Wire Mesh a versatile solution for numerous industrial, architectural, and specialized applications.

| Mesh | Open Area | Wire Diameter | Weaving methods | ||

| inch | mm | Max(mm) | Min(mm) | ||

| 4″ | 4 | 101.6 | 12.7 | 6 | Intercrimp/Lock |

| 3″ | 3 | 76.2 | 12.7 | 5 | Intercrimp/Lock |

| 2″ | 2 | 50.8 | 10 | 4 | Intercrimp/Lock |

| 1 1/2″ | 2 | 38.1 | 10 | 3 | Intercrimp/Lock |

| 1X2″ | 1X2 | 25.4X50.8 | 8 | 2.5 | Intercrimp/Lock |

| 1″ | 1 | 25.4 | 8 | 2 | Plain /Intercrimp |

| 3X4″ | 0.75 | 19.05 | 6 | 1.8 | Plain /Intercrimp |

| 5X8″ | 0.62 | 15.8 | 5 | 1.5 | Plain /Intercrimp |

| 2 | 0.5 | 12.7 | 4 | 1 | Plain /Intercrimp |

| 3 | 0.33 | 8.46 | 3 | 1 | Plain /Intercrimp |

| 4 | 0.25 | 6.35 | 2 | 0.8 | Plain /Intercrimp |

| 5 | 0.2 | 5.08 | 1.6 | 0.7 | Plain /Intercrimp |

| 6 | 0.17 | 4.23 | 1.5 | 0.6 | Plain /Intercrimp |

| 8 | 0.12 | 3.17 | 1.2 | 0.7 | Plain /Intercrimp |

| 10 | 0.1 | 2.54 | 1 | 0.6 | Plain |

| 12 | 0.08 | 2.11 | 0.9 | 0.5 | Plain |

| 14 | 0.07 | 1.81 | 0.7 | 0.5 | Plain |

Features

- Crimped wire mesh is valued for its durability, ease of maintenance, and aesthetic simplicity, making it a versatile choice for various applications. Its key features include:

- Vandal Resistance: Built to resist damage and tampering, enhancing its durability and longevity.

- Low Maintenance: Its robust construction requires minimal upkeep, making it cost-effective over time.

- Strength and Reliability: Provides secure barriers for protection, suitable for diverse environments.

- Simple Aesthetic: The straightforward design contributes to its visual appeal, allowing it to blend with any architectural style.

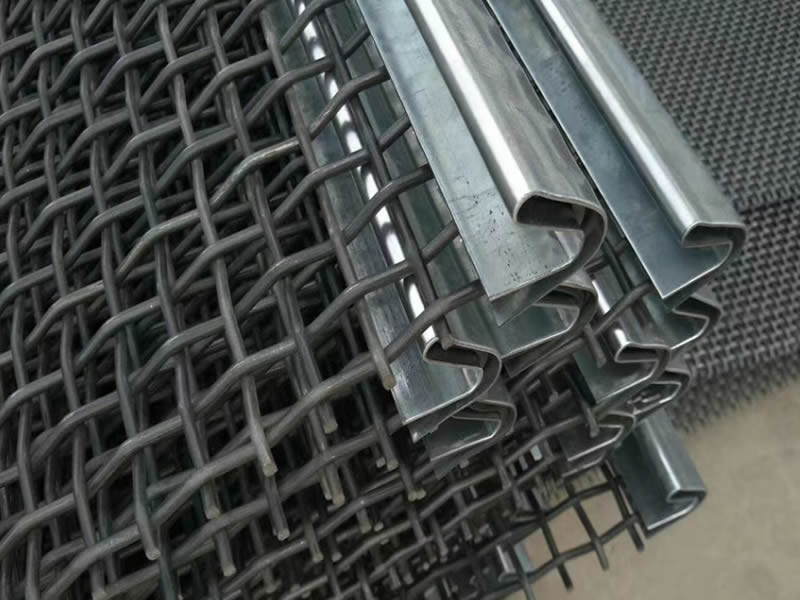

- Ease of Installation: Designed for quick and efficient setup, reducing labor costs and installation time.

- Lightweight for Transport: Easy to transport and handle, facilitating its use across different project locations.