Known as gas-liquid mesh, broken foam mesh, and filter mesh, this product employs a knitting method adapted from traditional techniques, optimized for mesh production to enhance its filtration and separation capabilities.

Constructed from round titanium wire with diameters ranging from φ0.08 to φ0.50mm, the mesh can also feature multi-strand braids from wires ≤φ0.30mm in diameter for increased strength. This versatile process supports both wire and fiber, enabling customization for various applications.

Specifications and Customization

- Wire Diameter Range: Titanium knitting mesh is designed with wire diameters spanning from 0.07mm to 0.55mm, with the most commonly used threads being between 0.20mm and 0.25mm. This range allows for flexibility in strength and texture, accommodating a variety of applications. Furthermore, multiple strands can be woven together to achieve desired thickness and durability.

- Opening Size Options: The mesh opening sizes vary widely, starting from small (2 × 3mm) to medium (4 × 5mm) up to larger openings (12 × 6mm). Customization is key, as opening sizes can be adjusted based on specific customer needs, providing a tailored solution for each application.

- Surface Conditions: Available surface conditions for the gas-liquid filter include both flat and corrugated mesh surfaces. The corrugated option offers varied specifications for both width and depth, catering to specific filtration and aesthetic requirements.

- Width Range: The gas-liquid filter is available in an extensive width range, including but not limited to 40mm, 80mm, 100mm, 150mm, 200mm, 300mm, 400mm, 500mm, 600mm, 800mm, 1000mm, 1200mm, and up to 1400mm.

Titanium knitting wire mesh stands out for its adaptability, with customizable wire diameters, opening sizes, surface conditions, and widths to meet a broad spectrum of needs. Whether for industrial filtration, architectural design, or specific technical applications, these customization capabilities ensure that clients receive a product precisely suited to their requirements.

Classification

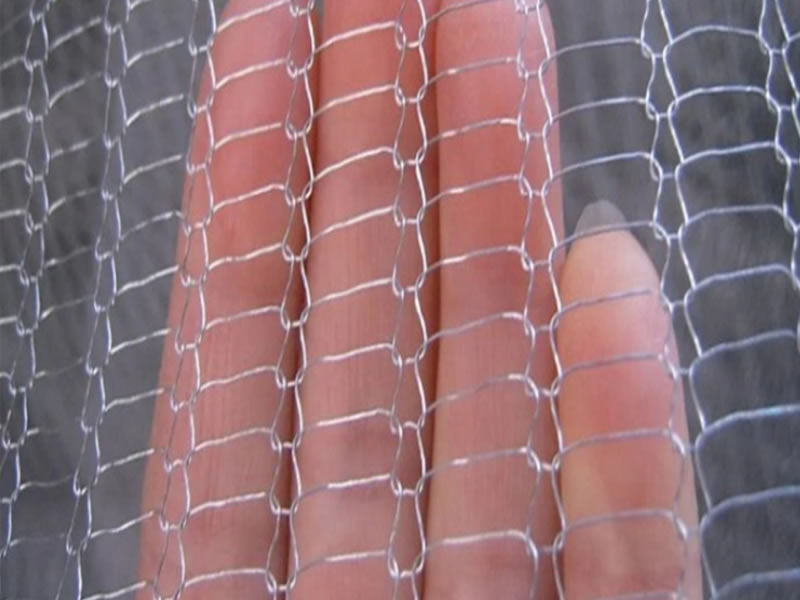

- Single Wire Titanium Knitting Mesh: Single wire titanium knitting mesh, known for its fine, precise structure, is perfectly suited for detailed filtration and separation. Constructed from a single strand of titanium wire, it ensures high precision and uniformity, crucial for filtering tiny particles in industries like pharmaceuticals and food and beverages. It excels in environments demanding accurate and consistent filtration.

- Multiple Wire Titanium Knitting Mesh: Designed for enhanced strength and durability, multiple wire titanium knitting mesh combines several wires into a braided structure. This robust composition is ideal for demanding tasks such as industrial filtration, noise reduction, and vibration damping in heavy machinery. It’s especially effective in handling higher pressures and harsh conditions, serving industries like automotive and petrochemicals well.

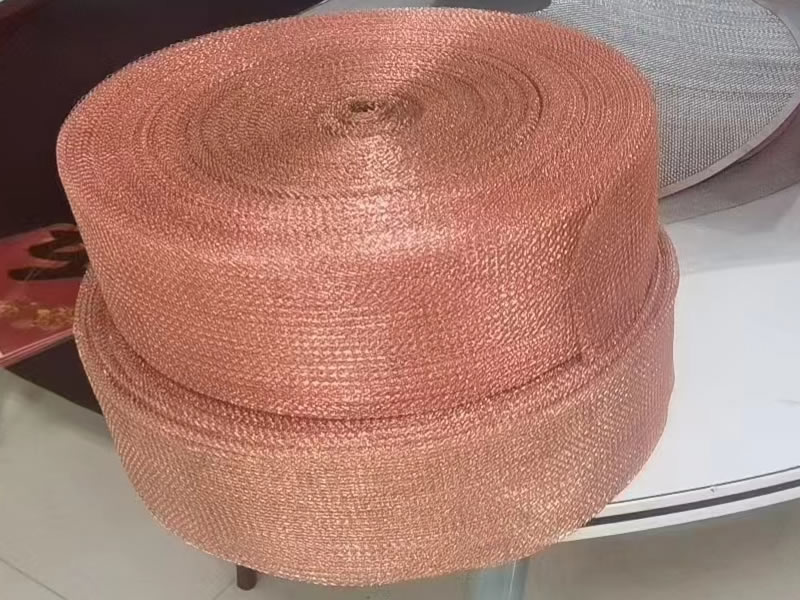

- One Roll Titanium Knitting Mesh: Offering unmatched flexibility and convenience, one roll of titanium knitting mesh caters to a wide array of industrial and architectural needs. Its roll form enables straightforward customization and installation, making it ideal for extensive projects like protective barriers, building facades, and environmental containment. The roll’s adaptability and titanium’s durability make it a versatile choice for projects valuing resilience and corrosion resistance.