Titanium’s properties are often enhanced by alloying with other metals, with meticulous attention to the perforation process, including pattern design, hole spacing, and material selection, to meet various requirements.

Its exceptional corrosion resistance, due to a stable oxide layer, extends its uses to chemical processing, desalination, power generation, and the creation of components such as valves, pump parts, marine hardware, and prosthetics, ensuring durability across multiple environments.

Titanium Perforated Sheet Specifications and Customization

Titanium perforated sheets are designed with a wide range of specifications to cater to diverse industrial and design needs. Key specifications include:

Aperture Size: The hole sizes in Titanium perforated sheets vary from as small as 0.5mm to as large as 50mm, accommodating a broad spectrum of applications from fine filtration to architectural design.

Sheet Width: Available sheet widths stretch from 10mm to a substantial 2400mm, ensuring suitability for both small-scale projects and large architectural applications.

Sheet Length: The length of Titanium perforated sheets starts at a minimum of 10mm, with no upper limit, allowing for the accommodation of extensive custom projects and applications.

Packaging: To ensure the integrity and quality of the sheets during transportation, we provide secure packaging solutions. This includes double-layer protection with wooden box packaging for structural strength and a waterproof compartment to guard against moisture damage.

These specifications highlight the adaptability of Titanium perforated sheets to meet specific project requirements. Whether for architectural elements, industrial use, or bespoke design projects, the range of aperture sizes, sheet dimensions, and secure packaging options offer comprehensive customization capabilities.

PURE METAL ALLOYS

Titanium perforated sheet metal is available in five grades of commercially pure titanium, ASTM Grades 1 through 4, and 7, each with varying impurity levels. Grade 1 is the purest, with a tensile strength of 172 MPa, while Grade 4 offers the highest strength at 483 MPa.

Alpha Alloys

Alpha titanium alloys, primarily containing aluminum and tin, are distinguished by their weldability and superior creep resistance. Ideal for cryogenic use, aircraft parts, and chemical processing equipment, they surpass the performance of beta alloys.

Beta Alloys

Beta titanium alloys are known for their excellent hardenability and formability after solution treatment, with strengths up to 1345 MPa. Denser than other types, they have densities between 4840 and 5060 kg/m3 and are particularly suited for demanding aircraft roles due to their weldability and lower creep resistance.

Alpha-Beta Alloys

These alloys leverage heat treatment for enhanced strength, combining ductility with hardening capabilities. Suitable for a wide range of applications, including aircraft and turbine components, chemical processing, marine hardware, and prosthetics, alpha-beta alloys are versatile and strong.

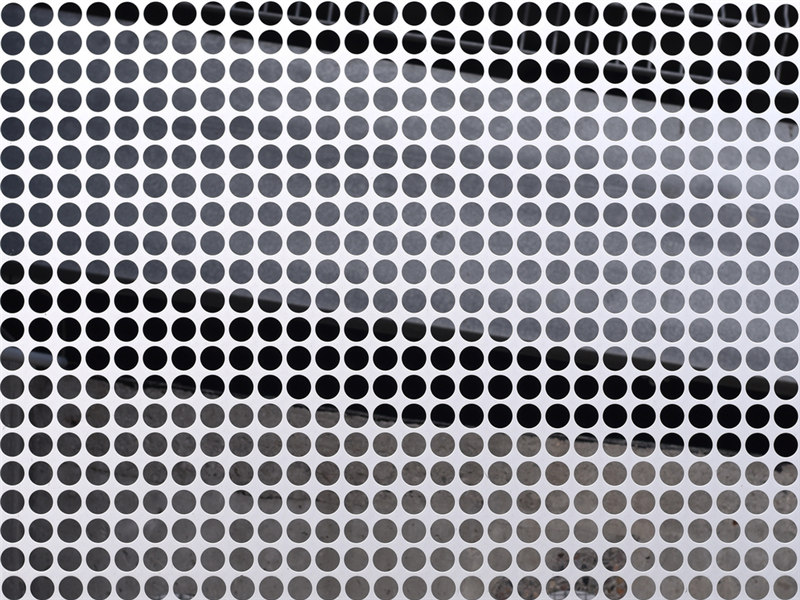

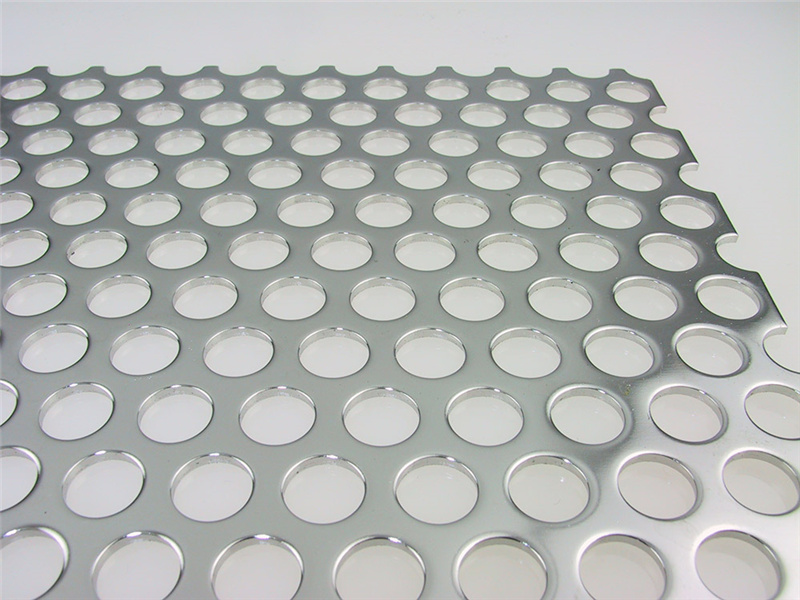

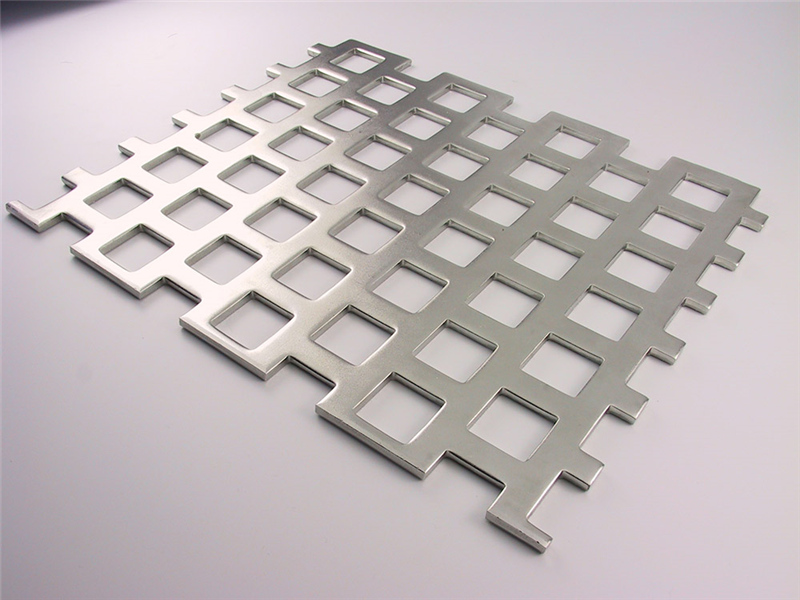

Types of Titanium Perforated Sheets

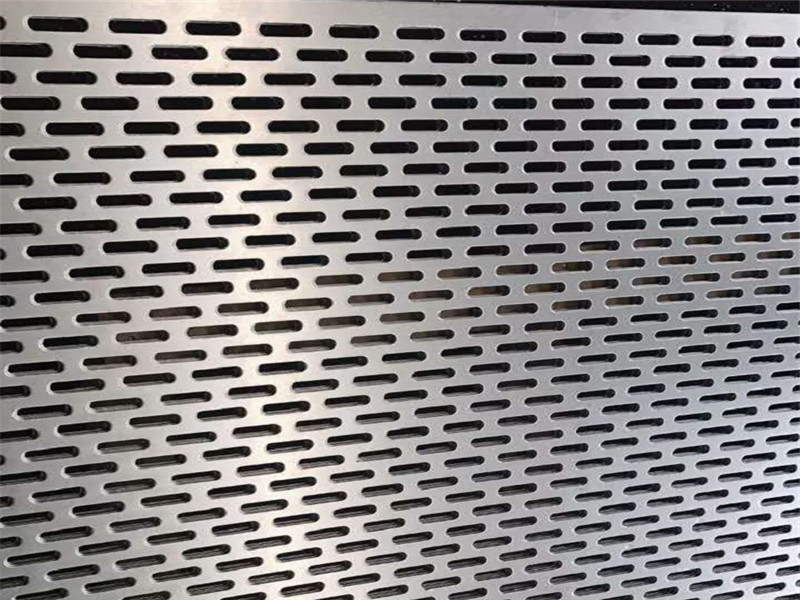

Titanium perforated sheets come in various designs based on hole sizes, shapes, and specific applications. Here are some common types:

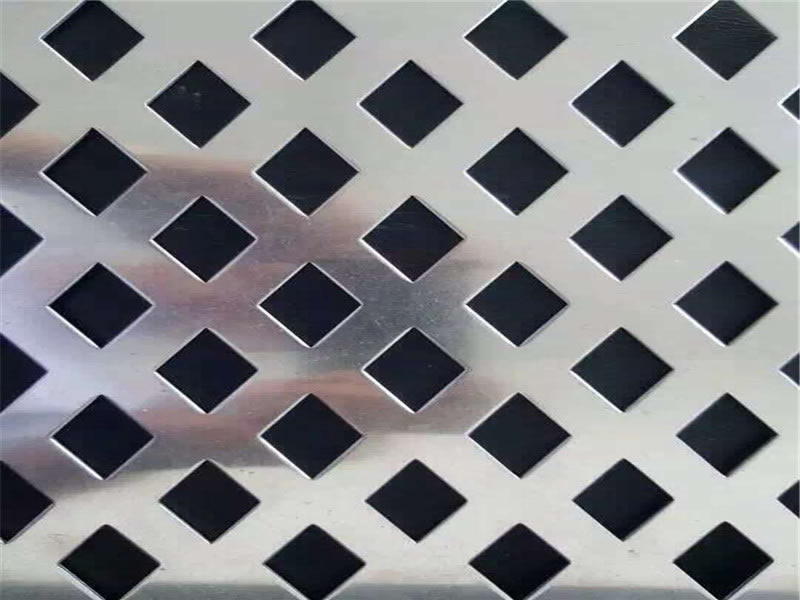

- Diamond Hole Titanium Perforated Sheet

Features diamond-shaped openings allowing for light, air, and sound passage. - Round Hole Titanium Perforated Sheet

Characterized by round openings, it’s widely used in filters, displaying straight rows of holes and is the most prevalent form. - Square Titanium Perforated Sheet

Square holes are mechanically punched into these sheets, available in numerous sizes and customizable to client specifications. - Triangular Titanium Perforated Sheet

With triangular patterned holes, this sheet combines aesthetic appeal with a high strength-to-weight ratio and a smooth surface. - Semi-Circular Titanium Perforated Sheet

Featuring semi-circular holes, these sheets are precise and commonly used for noise reduction in highways and public transport areas.

Each type of Titanium perforated sheet offers unique benefits, from aesthetic qualities to functional applications like filtration and sound dampening.